Use the links located on the left to view the instruction sheet for the product you are installing. GM 74L-454ci-V8 Engine Torque Specs.

716 Inner Main Caps 4 bolt Engine Oil.

Bbc cylinder head torque sequence. Make sure threads in the head are clean and in good. For Head Studs or aftermarket bolts CHECK YOUR INSTRUCTIONS BBC studs are available in a ton of different. Screw-In Rocker Arm Studs.

For what ever you use make sure the threads in the block are clean. Cylinder head 80 ft. Short bolts Rocker Studs screw-in Engine Oil.

In this example provided by Summit Racing you can see the torque sequence for a typical LS head. 16-19 in torque sequence M8 X 2550 in. 716 Main Caps 2 bolt Engine Oil.

Main Caps 396-427 2 bolt Engine Oil. Over 6000 Automotive Torque Specs. BBC L29 Vortec heads Mark IV cylinder heads on later Mark V block.

BR 7 LS7 Compatible Series Cylinder Heads12 BR 3 Series LS3 Compatible Series Cylinder Heads15 IK Series Cylinder Heads23 Race-Rite Small Block Series23 Dragon Slayer Series Cylinder Heads23 Track 1 Series Cylinder Head23 Head Hunter Series23 11 X. Torque to the head manufactures instructions in proper sequence and steps. You need the proper size spark plugs thread diameter depth install using a bit of antiseize.

Installation instructions are embeded into the page as a PDF document so you can save or print the instructions for later use. Connecting Rod 50 ftlbs. General Motors 74L Head Gasket Issue.

Between the head and the fastener to prevent galling. If you were to pocket-port these heads and add larger 219188-inch valves you could make 530-plus horsepower. Washer Studs 20 thru 23 screw into the bottom of the cylinder head and protrude into the lifter valley once the head is installed.

Once they are in place put a small amount of ARP moly lube on the tops of all washers. Coat all threads with Permatex 3H Aviation Form-a-Gasket follow Permatexs directions for set-up time then place the bolts in their proper locations. Main Cap Bolt 396-427 2-Bolt 95 ft-lbs.

Spark Plug 15 ft. Aluminum cylinder heads with factory bolts should be torqued to 70-75 ftlbs using Permatex thread sealant with Teflon. All aluminum cylinder heads should be torqued to 65ftlbs.

Washer 20-23 in torque sequence M8 X 2725 in. Long bolts 65 ft-lbs. The torque spec can be anywhere from 25-35 on Iron heads but for aluminum I tend to go towards the lower side.

38 Connecting Rod Cap. Use other gaskets at youre own risk- these are what you want from a VR press release presumably prior to the Gen 6 engine release. Cylinder Head To Engine Block 80 Ft-Lbs 960 In-Lbs 10847 N-m Years.

716 Connecting Rod Cap. Main Cap Bolt 396-454 4-Bolt Inner and Outer 110 ft-lbs. According to the 454 engine manual Torque Specifications oiled threads.

Place head bolt washers over each bolt hole. Be sure to follow the proper GM torque sequence starting at 40 ftlbs and increasing by 10ftlbs until reaching the recommended setting. Intake Manifold 30 ft.

This should be done in the proper General Motors sequence in 10-ftlb increments beginning at 40ftlbs. Engine oil blind hole Sealer water jacket 75 ft-lbs. Torque the bolts in the three stages.

716 Outer Main Caps 4 bolt Engine Oil. If you were looking to build a budget-oriented Rat for towing where power above 4500 rpm was not a concern these heads would be an excellent choice with almost 600 lb-ft of torque at 3200 rpm. Exhaust Manifold 20 ft.

Youll need hardened pushrods to work with guide plates. IF you do have a spec from the manufacturer follow that. Main Bearings 110 ft.

Search Car Torque Specifications by Engine or Model. Cylinder Head Bolts Long. It doesnt hurt to run a tap on every bolt hole.

These heads are 100 CNC ported and utilize features such as raised oval-shaped intake ports that flow an amazing 489 cfm and up and newly designed exhaust ports that flow 335 cfm with only a 1850 exhaust valve. Intake Manifold Bolts Cast Iron Head. The BRODIX Head Hunter series represents the cutting edge of conventional big block technology.

Installation Instructions for AFR Heads. Small Block Chevrolet Compatible Heads. 50 torque OK lets just say 35 FtLbs then final round at specs.

Styles depending on heads and stud diameter 716 and 12. Engine oil blind hole Sealer water jacket 65 ft-lbs. The pattern for most heads will start in the center and then hop back and forth towards the outer.

Moly lube should be applied between fasteners washers and areas around head bolt to prevent galling and improper torque values. Cylinder Head Bolts Short. 38 Outer Main Caps 4 bolt Engine Oil.

There are gaskets made specifically for this swap. Main Caps 396-454 4 bolt Inner and Outer bolts.

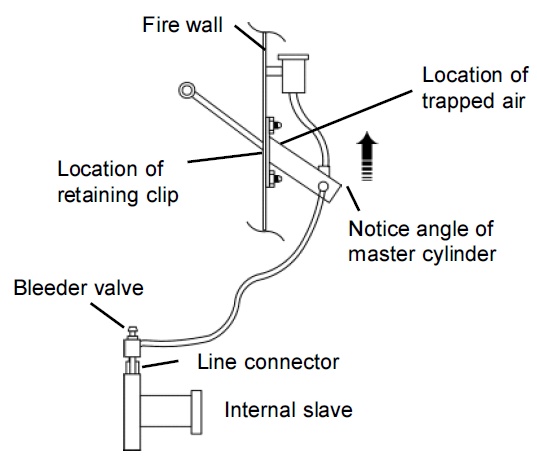

Gen2 k8 clutch slave cylinder seal. If you still arent sure what the problem is then take a look under the hood and examine the master cylinder itself.

Ford Ranger Clutch Problems Explained

Ford Ranger Clutch Problems Explained

Fixing the slave cylinder yourself The fix is pretty simple order the Oring replacement it is EPDM o-ring 22mm ID and 25mm thick.

Clutch slave cylinder problems. Even the smallest amount of air in the lines can prevent proper operation. When the problem occurred it was as if the clutch pedal were engaged. Abnormal clutch pedal behavior.

A clutch that fails to release when the clutch pedal fully depresses can prevent an operator from shifting. One of the commonest symptoms of a failed clutch slave cylinder is also one of the easiest to spot youll notice that the clutch pedal feels soft as you drive. 21 people reported this problem 10 comments Mazda MX-5 Miata Vehicles With This Problem.

Symptoms of a Bad Slave Cylinder Loose Pedal. If a slave cylinder is. Then bleed the clutch system to get any air out.

Low or contaminated brake fluidLow or contaminated fluid in the reservoir is another symptom commonly associated. Worn hydraulic components can cause clutch release problems. Abnormal clutch pedal feelOne of the first clues of a potential problem with the clutch master cylinder is abnormal.

Fluid leaking from. Once we replaced the clutch flex hose the slave and the master were so worn out that they too had to be replaced. Here are some of the warning signs of a bad clutch slave cylinder.

The pedal will offer your foot less resistance than usual and this problem is typically caused by a leak in either the master or slave cylinder. The clutch slave cylinder receives fluid pressure from the master cylinder when the clutch pedal is pushed. Low or contaminated brake fluidLow or contaminated fluid in the reservoir is another symptom commonly associated.

A failing clutch master cylinder will lose its power to maintain the hydraulic pressure needed for the clutch to function. Clutch Slave Cylinder W0133-2202006-LUK by LuK. If discovered identify and replace the bad lines or seals.

If the bottom of the cylinder feels wet then the leak is probably coming from the master cylinder. We discovered that the clutch flex hose had fallen apart on the inside and was blocking hydraulic pressure to the slave cylinder like a one-way valve. If none of these helped the slave cylinder master cylinder or both likely need to be replaced.

Hi i have a gen2 k8 does anyone know if the gen2 clutch slave cylinder seal kit are the same as other models I have phoned to get the kit and they only list 99 to 04 kits. Monitoring clutch fluid levels may help with diagnosing a bad slave cylinder. Leaks on the floor or engine bay.

Worn or ill-fitting seals may allow hydraulic fluid to leak past the piston in either cylinder so that the slave piston does not travel far enough to disengage the clutch. LuK offers a complete line of high-quality slave and master cylinders for import and domestic vehicle applications. Clutch Slave Cylinder Troubleshooting Soft Clutch.

Hard to shiftAnother symptom commonly associated with a bad or failing clutch master cylinder is difficulty shifting. The way a clutch pedal feels when pressed will often indicate if a slave cylinder is faulty. Clutch does not work Clutch pedal sinks to the floor Clutch pedal feels spongy soft or loose Clutch pedal feels hard Gears grind while shifting Gears are hard to shift Gears will not shift Clutch fluid low andor leaking Engine.

In a hydraulic clutch however the problem may lie in the master or slave hydraulic cylinders. Abnormal clutch pedal feelOne of the first clues of a potential problem with the clutch master cylinder is abnormal. Before replacing your cars clutch check the master slave cylinder.

The clutch slave cylinder may develop a hydraulic leak resulting in no clutch pedal pressure and the inability to shift gears. Start date May 31 2020 More options Meta tags. A bad seal in the clutch slave cylinder can leak fluid and allow air in the line resulting in a soft.

Could Save Big On the way to work one day I noticed that my clutch pedal was softer. Signs that the clutch slave cylinder is failing can include a low clutch pedal a clutch hat wont disengage or fluid leaks on the floorboard. Low or dirty clutch fluidOne of the first symptoms commonly associated with a potential problem with the clutch.

This pressure allows the clutch slave cylinder to release the clutch. Any sort of leak will have the same effect and air might get into the system. Symptoms of a Bad or Failing Clutch Slave Cylinder 1.

Next take the slave cylinder off.

For each cylinder head start with head bolt numbered one. The connecting rods torque to 29 foot pounds.

B3 Diesel Engine Mechanical Cylinder Head Bolt Tightening Torque

3 Tighten each bolt to 22-25 foot pounds of torque.

Torque for cylinder head bolt. Starting over at Bolt 1 you goe through the torque sequence again only this time dont use a torque wrench. These bolts achieve clamping force by stretching during the torque process. In this video I show a general over view on how to torque cylinder head bolts.

L-Head AluminumCast Sleeve Single Cylinder. L-Head AluminumCast Sleeve Single Cylinder. You really cant tell if a bolt is TTY by.

In the second step bring the torque to 20 foot-lbs. Let me know if that helps or if you have other questions related to the head. Whenever the size difference between d1 and d2 exceeds the limit replace the bolts with new ones.

How To Torque Cylinder Head Bolts Some cylinder heads like this BMW M20 engine require you to torque down the head bolts first to a torque value and then to. First following the torque sequence. Cylinder head bolt torque sequence-16L engine Access our Aveo 2004-2005 Cylinder Head Repair Guide Removal and Installation by creating an account or signing into your AutoZone Rewards account.

In the third step bring it up to 40 foot-lbs. Once you sign in follow these instructions to access our Repair Guides. Begin with the center bolt 11 and alternating side-to-side work outward.

Make Liter CID Engine Model Year Rod Torque Main Torque Cylinder Head Bolt Torque ALLIS CHALMERS 15 90 66-73 FTLBS 80-106 FTLBS 119-146 FTLBS ALLIS CHALMERS 19 116 PIN CLAMPING BOLT 35-40 FTLBS 65 FTLBS ALLIS CHALMERS 19 116 35-40 FTLBS PIN CLAMPING BOLT 35-40 FTLBS 80 FTLBS 65 FTLBS ALLIS CHALMERS 20 120 60 FTLBS. If an engine produces 1500 pounds of pressure and the cylinder head has 8 bolts then each bolt must be tightened to 187 foot-pounds of torque to secure the cylinder head to the block. BOLD THE TWO MEDIUM LENGTH BOLTS IN EACH UPPER CORNER 104.

Thak You for using FixYa. If cylinder head bolts are re-used check their outer diameters before installation. Tighten each bolt to 7-9 foot pounds of torque.

10A000 Thru 10M000. Tighten the M11 cylinder head bolts 1-8 to 90 degrees and the M11 cylinder head bolts 9 and 10 to 50 degrees a final pass in sequence. L-Head AluminumCast Sleeve Single Cylinder.

Head bolts are being torqued to the specified value the technician can use the TRQ-1 tool to accurately measure the degrees of additional rotation required. Before doing this however be sure to check the factory service manual of you. The manufacturer may state to bring all the bolts to 10 foot-lbs.

L-Head AluminumCast Sleeve Single Cylinder. Tighten the M8 cylinder head bolts 11-15 to 30 Nm 22 lb ft. Click to see full answer In this regard what is the torque specs for head bolts.

In increasing number sequence 1-2-3-4 tighten the head bolt in four stages. Cylinder Head Torque Specification Lookup Year Click to View PDF Guide. Torque the head bolts in the same manner in three stages.

A torque to yield fastener TTY or stretch bolt is a fastener which is torqued beyond the state of elasticity and therefore undergoes plastic deformation causing it to become permanently elongated. L-Head AluminumCast Sleeve Single Cylinder. Cylinder head bolts are tightened by plastic zone tightening method.

Hub Wheel Bearing. This eliminates guesswork and assures more consistent results. The correct Main bolt torque is 42 foot pounds.

Many modern engines use Torque-To-Yield TTY bolts which cant be reused. Torque Specifications for Ford 54L-330ci-V8. Camshaft To Cylinder Head.

Bringing the torque up in incremental steps prevents head warping as well. The torque sequence for the head bolts and the correct way to tighten the bolts are attached to this reply. Following the sequence laid out in the diagram for the 14 head bolts you torque them to 55 Nm about 41 lbft.

Tighten each bolt to 12-15 foot pounds of torque. Torque-To-Angle Indicator Part Number TRQ-1 Head Bolts Previously installed Torque-to-Yield head bolts should never be reused.