Lets take a closer look. Both of these types of brakes require specialized experience and dont perform well in water or extremely cold conditions.

Spec Ing Trailer Brakes Know The Uses Know The Laws Trailer Body Builders

Spec Ing Trailer Brakes Know The Uses Know The Laws Trailer Body Builders

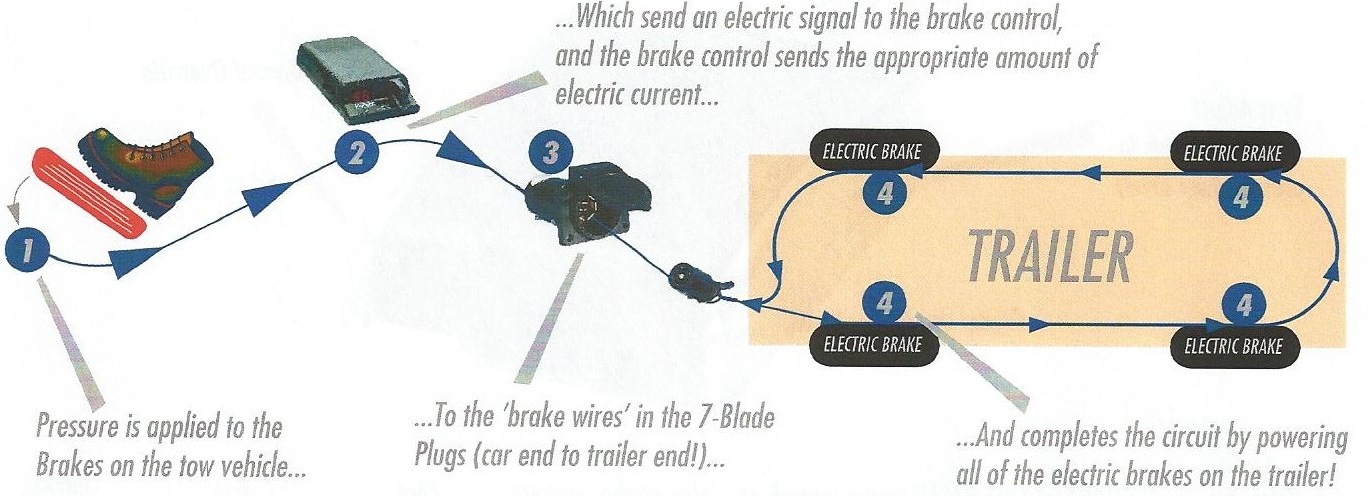

While less expensive when buying the trailer electric brakes will require a brake controller at the dash of the tow vehicle adding an expense if the tow vehicle isnt already equipped.

Types of trailer brakes. SAE J560 is typically used on heavy duty trucks and trailers with pneumatic brakes where only the power to the ABS unit and indication of braking by brake light signal is required. Surge brakes require no electrical connection from the towing vehicle. Air-actuated electric brake controller This controller uses the air pressure of the brake system on a vehicle with pneumatic brakes to provide a current to control the electric brakes of a trailer.

But to simplify the conversation there really are just two main types of brake controllers to choose from. Proportional controllers and time-delayed controllers. Types of Travel Trailer Braking Systems Electric Brakes.

Not all trailer brakes are capable of wheel lockup. Trailer brake controllers can be split into two main categories. Time-delayed or stable state brake controllers and proportional ones.

Includes electric brake assemblies hubs drums bearings races seals and mounting. A guide to trailer brakes Override brakes. Trailer axle measures 89 from hub face to hub face and 74 from spring center to spring center.

Using a brake controller while towing a trailer involves setting up the controller adjusting to the load size adjusting braking sensitivity manually activating the trailer brakes and possibly choosing a few personal settings. Electric Over Hydraulic Brakes use an electrically powered actuator that is controlled through the tow vehicles braking system which allows the actuator to create the hydraulic pressure to slow and stop the trailer. The brakes themselves are controlled using air pressure.

Of your wheels the brake type and the aforementioned lengths. Boating enthusiasts would say that hydraulic surge brakes are the simplest to use for boat trailers. Hydraulic Surge Brakes use momentum and resistance.

Hydraulic actuated electric controller. Surge brakes remove safety hazards in the water and with operators who arent familiar with other trailer brake systems. This is thanks to the internal accelerometers that proportional controllers use to monitor your vehicles speed and braking force.

As the vehicle stops the trailer surges forward which allows the actuator to create hydraulic pressure to slow and stop the trailer. Mechanical override brakes use the tow coupling to manually pull a cable connected to the trailers. Disc brakes can replace most drum systems with minimum modifications and offer the following advantages over drum brakes.

A proportional controller uses a sensor to determine the intensity of the tow. The surge brakes use the trailers momentum and own weight which pushes against a hydraulic cylinder when you step on the towing vehicles brakes. In this guide we will unpack how a trailer brake controller works and the steps involved in how to use a brake controller while towing with trailer brakes.

This system functions on pre-determined braking capacity that is set by the user and is based on the weight of the trailer plus the weight of the anticipated cargo. Fundamentally a lot of experts highly recommend them on trailers that are graded for 1500 pounds and beyond. Which Boat Trailer Brake Type Should I Use.

Boat trailer brakes need to be marine grade and the electrical components have to be sealed against water intrusion. The least expensive brakes to install on the trailer are electric drum brakes. Trailer brakes are either disc or drum brakes.

Self-cleaning and lower maintenance. In addition in the US you need to have what is called a breakaway system. Surge type travel trailer brakes.

Dexter Axles Dexter axles are made of high-strength steel and come with spindles and spring seats welded on. Electric brakes and surge brakes. Brakes for boat trailers could be hydraulic electrical or mechanical in form.

Loading conditions brake type wheel and tire size can all affect whether a brake can lock. There are two types of trailer brakes. The rate of your trailer braking is proportional to the rate of your tow vehicle brakes.

The first surge brakes operate on an automatic hydraulic braking system. There are a different types of brake controllers that are currently or previously on the market. The actuating cylinder.

The other types of brakes found in trailers are electric trailer brakes and air brakes. On a travel trailer you will typically find 2 types of brakes. A hard stop is a hard stop and a soft stop is a soft stop every time.

They are automatically applied by the brake controller and can be manually operated by a manual. Better resistance to fade when descending a mountain pass or in stop-and-go traffic. Some states require brakes to be equipped on trailers with a total weight of more than three thousand pounds.

Therefore a surge braking system does not require a brake controller to function. According to the California Department of Motor Vehicles most travel trailers use electric brake. Adjust the controller just to the point of impending brake lockup and wheel skid.

If the trailer brakes lock and slide decrease the gain setting.

Electric trailer brakes are available as complete assemblies ready to bolt to the axle and connect the wires. Like the hydraulic counterparts rust and corrosion is a problem on any brake system.

Etrailer Hydrastar Marine Electric Over Hydraulic Actuator Installation Youtube

Etrailer Hydrastar Marine Electric Over Hydraulic Actuator Installation Youtube

Electric Over Hydraulic Brakes use an electrically powered actuator that is controlled through the tow vehicles braking system which allows the actuator to create the hydraulic pressure to slow and stop the trailer.

Electric brakes boat trailer. Traditionally trailer manufacturers did not use electric brakes on boat trailers because the brake magnet wiring and trailer wiring did not always have the best insulation or water protection. RV-grade systems with painted automotive-grade components are not intended for submersion especially in salt water. 2-Pack Trailer Brake Backing Plates 10 in.

The latest Al-ko model has the advantage of a built-in park brake function and has the latest technology in hydraulic electric actuators. Electric brakes are the most common braking system on trailers. However few boat trailers are equipped with electric brakes but theyre used on many RV and utility trailers.

They have a greater pressure that works well in water. The problem with this is that they may not be suitable for salt water. The electric over hydraulic brake systems requires a control signal from an electric brake controller Elecbrakes provides this functionality and furthermore allows the user to precisely adjust the proportional brake response to suit the towing conditions.

Electric Brakes on Boat Trailer You can lock up the electric brakes from the tow vehicle anytime you want by manually powering them via the controller. Ive heard that electric-over-hydraulic brakes are making inroads into the boat trailer market. How Electric Trailer Brakes Work.

You can do this by firstly towing your trailerboat to a quiet road with the boat on the trailer of course and with brakes dry - not just after dipping it into the water. All KodaGuard calipers undergo a test in which they are sprayed with a 5-percent salt. It is a simple system and parts are easy to change if necessary.

The trailer always brakes first and this positive brake action is safer for downhill driving and quick stops. The friction created by the internal mechanisms makes the boat trailer stop faster and has greater resistance to the water. 2LH 2RH w4 HubDrum Kit 5 on 45 46 out of 5 stars 55.

Boat trailers over 2000kg typically use an electric over hydraulic brake system this is due to complete electric brake systems not being viable in the marine environment. These days more and more manufacturers are using electric brakes on boat trailers due to improvements in wiring insulation and heat shrink connectors. Yes -- boat trailers can utilize electric brakes.

You can adjust the sensitivity of braking based on your load. Electric brakes though do not apply as much force against the tow vehicle as hydraulic brakes. In general these electric boat trailer brakes are smart investments they can function outstandingly and they do not force you to spend extravagantly on premium quality braking system.

You have to set up an electric brake controller for the trailer brakes to work effectively. Electric brakes use electromagnets to actuate the drum brakes and you control the electricity to the brakes with the brake controller and the brake light circuit on your vehicle. Ei Trailer Brake Assembly Electric Trailer Brakes 12 x 2 - 2 right 2 left 5200 6000 7000 lb axles.

Electric Trailer Brake Assemblies Trailer Parts Superstore sells 22k thru 15k capacity electric trailer brakes and brake parts from Dexter Rockwell Lippert Fulton and other top name manufacturers. Includes 2 KodaGuard-plated calipers 2 Dacromet-plated hub rotor assemblies and brackets 4 stainless steel caliper mounting bolts. Boat Trailer Disc Brakes are designed specifically of Coated and Stainless materials to resist corrosion Disc Brakes are ideal for Saltwater Boat Trailers as all the components can be either rusts resistant or stainless steel and rust resistant.

47 out of 5 stars 246. Electric-over-hydraulic systems are great for larger boat trailers because they offer the benefit of adjustment and smoother operation but they are more costly than conventional surge-brake systems. As a result preventing the dangerous jack-knifing skid effect.

Resistance for Marine Use This disc brake assembly resists corrosion making it ideal for use on your boat trailer. Electric brakes are more simple than surge brakes but they require a brake controller in the cabin of the tow vehicle. With both of these options you can use either Disc Brakes or Drum Brakes mounted to the axle.

The Alko boat trailer brake actuator ensures trailers brakes operate simultaneously with the brakes on your tow vehicle. They are different than hydraulic brakes in that when you apply pressure to the tow vehicles brake pedal pressure is also applied to the trailer brakes. Rust-resistant disc brake kit is great for boat trailers.

You can set the trailer brakes to come on as soon as you touch the brake pedal andor just let them work automatically. Disc brakes are characterized by power. The electrical components are potted so electrical issues are not a problem.

They are equipped with dependable stopping power and can handle 6000-pound capacity onboard.

First chock the wheels or connect the trailer to its tow vehicle to ensure it doesnt move then jack up the boat trailer and remove the wheels hubs hydraulic brake lines and existing brake system 1. Adjusting the Brakes.

Atwood Hydraulic Brake Actuator Parts List And Schematic Pacific Trailers

Atwood Hydraulic Brake Actuator Parts List And Schematic Pacific Trailers

Shop for complete foundation brake assemblies that bolt right to the axle flange new brake drums with or without wheel bearings brake lines and hydraulic brake actuators.

Boat trailer brake repair. Inspect the axle spindle to ensure it is in good shape 2. We also specialize in Mercury Optimax Mercury Verado Evinrude E-Tec and just about every outboard motor ever built. Bleed the brake system if the brakes completely fail or work intermittently.

This time Im replacing the hydraulic brakes and seals on my boat trailer. Is there enough fluid inside the brakes master cylinder. If you dont find any replace the master cylinder.

Periodic maintenance is required but simply follow the manufacturer recommendations to get the most out of your hydraulic surge brakes. Direct a helper to slide in the surge pushrod at the front of the trailer. Adding hydraulic disc brakes to your Load Rite boat trailer is an excellent choice since you wont have any electrical components so your trailer can safely be backed into water.

Bleed the lines and adjust the brakes. BOAT TRAILER BRAKES Here at RM Marine we specialise in boat trailer brake service and repairs. In this Weekend Workbook article Jim Hendricks of Boating Magazine describes the procedure for replacing a malfunctioning boat trailer surge brake actuator-coupler.

Boatmasters is Located in Livermore California and provides San Francisco Bay Area residents with boat repair boat storage marine maintenance fiberglass repair prop rental trailer repair and boat sales. This category contains all the needed components for you to put together your ideal trailer axle kit to get your boat back in the water. Learn what tools youll need how much time to budget and more.

Hubs and Brakes Long-lived easy-to-lubricate Super Lube hubs included on all TRACKER trailers keep your ride smooth and your mind at ease delivering years of reliable performance. If that doesnt work remove the brake line from the back of the master cylinder and press the surge coupler. Is there air in the lines.

Selecting the correct boat trailer brakes to replace your existing system can be difficult. Said Called in several Auto Repair shops the day before many of the shops didnt pick up and I got to Lifetime Muffler Brake Radiator brought my car in at 9am. In addition adding brakes to your boat trailer can seem quit extensive.

Heres another quick Wild Card Wednesday video. Connect a bleeder hose to the bleed fitting and sink the other end in a cup full of brake fluid. Re-install your tires and rims on the trailer at this time and find the brake adjusting slot at the bottom rear of each brake backing plate There will usually be two slots on the back lower side of the backing plates.

Trailer surge brake actuator repair parts and accessories. LIMICAR 2020 Submersible Trailer Light Kit Upgrade LED Low Profile Brake Stop Turn Tail License Lights for Truck Marine RV Boat Camper Trailer Snowmobile Under 80 Inch IP68 Waterproof 45 out of 5 stars 44. One of the most important things is your trailer brakes especially if your boat weighs at least 1500 pounds.

These backing plates are universal and can be used for either RH or LH units. We have all the technical expertise needed on staff to walk you through the process. We carry many parts for Demco Titan Atwood and other surge brake actuator brands.

Back when the manufacturing technology for trailer brakes was not as technologically advanced as they are now. Fill the brake reservoir with automotive brake fluid. Whether you are preparing for an upcoming fishing trip with your family or just taking your boat for a spin it is always important to have your boat trailer parts in check.

Use a screwdriver to open the bleed screw fitting. Trailer Parts Superstore offers a wide selection of hydraulic drum brakes and drum brake parts for trailers of all sizes. Relevance Name A to Z Name Z to A Price low to high Price high to low.

And each trailer is custom built for each boat model making the fit as impressive as the constuction. Boat Trailer Axle kits include several different individual trailer parts. Surge Brake Maintenance One reason surge brakes are the most popular trailer braking technology is because the entire system is contained in the trailer itself.

If fluid doesnt come out check for obstructions. Auto Repair RV Repair Trailer Repair Justin L. The most integral parts of your boat trailers running gear would be the boat trailer axle and the trailer hubs.

Our team of qualified technicians have years of experience working with trailer brakes from simple brake caliper rebuilds to retrofitting electrichydraulic brake systems. Give us a call or send us an email and we would be happy to help. On top of that when compared to hydraulic drum brakes disc brakes stop harder and require less maintenance.