This means the vehicles ECM Electronic Control Module has not yet detected the crankshaft position sensor during the first second of cranking of the engine. Greg 3 months ago.

P0340 Code Camshaft Position Sensor A Circuit Malfunction In The Garage With Carparts Com

P0340 Code Camshaft Position Sensor A Circuit Malfunction In The Garage With Carparts Com

Hopefully the shop your at has decent diagnostic skills and theyll be able to figure out the problem.

Camshaft position sensor circuit malfunction. Sometimes and in some models low battery voltage or a weak starter can trigger a Camshaft Position Sensor code. The camshaft position sensor senses the piston position. 1995 through 2003 Chrysler 20L - 24L engine cam sensor replacement.

Analyze the camshaft position sensor - Visually analyze the camshaft position sensor bank 2. Grounded broken or shorted wire or connector in the circuit. This can happen for multiple reasons and a mechanic needs to diagnose the specific cause for this code to be triggered in your situation.

If the reluctor ring appears in good condition replace the camshaft position sensor. A P0340 means that there is a malfunction in the circuit of the Camshaft Position Sensor A. P0340 no start check engine light.

Poor electrical connection of the camshaft position sensor. The changing gap causes the magnetic field near the sensor to change. There exists an open circuit.

Sensor A indicates that the malfunction is occurring with the camshaft position sensor circuit that pertains to the intake camshaft. Here are some things to try. If your engine has only one CMP such as an inline-four-cylinder the only CMP code available is for Bank 1 P0340.

The changing gap causes the magnetic field near the sensor to change. This cycle may repeat intermittently. The error code P0340 most likely means that one or more of the following has happened.

Chrysler P0340 Cam Sensor Replacement - YouTube. Be on the lookout for corrosion frayed or broken wirings on the sensor. The symptoms of DTC P0340 can include the following.

A damaged or failed camshaft or crankshaft position sensor. It is considered generic because it applies to all makes and models of vehicles 1996-newer although specific repair steps may be slightly different depending on the model. On some vehicles a failing camshaft sensor may lock the transmission in a single gear until you turn off and restart the engine.

With a P0340 OBD-II trouble code diagnosis can be tricky at times. This can mean that there is a faulty camshaft position sensor or the wires on the way to the sensor. Visually inspect all the wiring and connectors in the circuit.

When the engine is running the high and low parts of the teeth cause the gap with the sensor to change. The camshaft position sensor may have failed. The PCM may have failed.

Engine hard to start or wont start at all. Our certified mobile mechanics can come to your home or office to perform the Check Engine Light diagnostic. A P0340 error code only indicates a circuit malfunction which could be caused by a number of components.

Symptoms of DTC P0340. A connector or wire in the route circuit could be broken shorted or grounded. There could be an issue with the camshaft position sensors circuit eg a damaged wire or poor connection.

The crankshaft position sensor may have failed. A failing camshaft position sensor CMP sensor can produce a confusing range of problems depending on the way it fails and the model of the car. Sensor B codes pertain to the exhaust camshaft.

The code may also set due to a problem with the camshaft timing the camshaft sprocket or the camshaft itself. On the other hand V6 or V8 engines have two banks Bank 1 and Bank 2 and would therefore have two CMPs so DTC P0345 would refer to Bank 2. 2003 Chrysler Neon 20L engine.

Camshaft Position Sensor A Circuit Malfunction Bank 2 What does that mean. If you find that the camshaft position sensor fails to produce a voltage or a signal remove it and check the reluctor ring for damage debris or misalignment. The problem could be a defective CMPS open or shorted wire or defective ECU.

The sensor system consists of a rotating part typically a disc as well as a static part the actual sensor. Analyze the connectors - Next you must search the bank two camshaft position sensor and denote any broken or corroded connectors. The sensor system consists of a rotating part typically a disc as well as a static part the actual sensor.

The harness of the camshaft position sensor is shorted or open. Just dont get confused with a bad camshaft timing with this trouble code. The CMPS electronic circuit consists of the Camshaft Position Sensor wiring harness and the ECU.

P0340 is a diagnostic trouble code DTC for Camshaft Position Sensor Circuit Malfunction. Overview Error Code P0335 is described as Crankshaft Position Sensor A Circuit Malfunction. When the engine is running the high and low parts of the teeth cause the gap with the sensor to change.

P0345 is a diagnostic trouble code DTC for Camshaft Position Sensor A Circuit Malfunction Bank 2. The camshaft position sensor senses the piston position. Youll need to carefully inspect your sensor and wiring to determine the exact cause.

This diagnostic trouble code DTC is a generic powertrain code. This can happen for multiple reasons and a mechanic needs to diagnose the specific cause for this code to be triggered in your situation. If the ECU cannot detect a CMP signal it will set DTC P0340 or DTC P0345 Camshaft Position Sensor Circuit Malfunction.

Check here for special coupons and promotions. Order Throttle Position Sensor for your 1989 Chevrolet S10 and pick it up in storemake your purchase find a store near you and get directions.

Throttle Position Sensor Symptoms And Fix Tps Youtube

Throttle Position Sensor Symptoms And Fix Tps Youtube

The computer then determines the position of the throttle plate.

S10 throttle position sensor. 2002 Chevrolet S10 Throttle Position Sensor Customer Reviews. When it comes to your Chevrolet S10 you want parts and products from only trusted brands. Replacement Idle Control Valve and Throttle Position Sensor Kit.

40 out of 5 stars 25. This sensor can fail gradually or all at once. Coolant Leak Diagnosis 44 - 56 in Nogales AZ.

Replacement Idle Control Valve and Throttle Position Sensor Kit. This video applies to ALL ChevyGMC trucks AND SUVs from late. Replacement Throttle Position Sensor.

No scan tool needed. Your order may be eligible for Ship to Home and shipping is free on all online orders of 3500. The Throttle Position Sensor monitors how far open the throttle valve is which is why it is most commonly found on the throttle body.

It also calculates the amount of air flow to the engine and the amount of fuel to be injected for the required ratio of air-fuel mixture. It then reports this information to your engines computer and the anti-lock braking system. Free Same Day Store Pickup.

2002 Chevrolet S10 Estimates. DOICOO Throttle Position Sensor TPS Sensor 17112714 213-894 17087655 for Buick Regal Cadillac Chevy S10 Blazer Camaro Cavalier Corsica Caprice Corvette Beretta Pontiac Olds Isuzu GMC Fit 17083333. We currently carry 11 Throttle Position Sensor products to choose from for your 1995 Chevrolet S10 and our inventory prices range from as little as 2284 up to 9031.

This helps your ECU control the fuel and air mixture. The throttle position sensor can fail in several ways all of which result in poor fuel economy at best and performance limitations that may create a safety hazard for you and other motorists at worst. That means it cant calculate the fuel and air ratio.

Engine Front Cover Gasket Replacement. 1995 Chevrolet S10 Throttle Position Sensor Customer Reviews. Advance Auto Parts has 36 different Throttle Position Sensor for your vehicle ready for shipping or in-store pick up.

Duralast Throttle Position Sensor TPS TPS112. Running great now great part. Purchased on Nov 22 2020.

Testing the throttle position sensor on your 1986-1991 28L V6 equipped S10 or S15 is a pretty simple and straightforward process. After all the accelerator pedal is connected to the throttle plate via a cable. Purchased on Apr 17 2019.

No parts for vehicles in selected markets. In most of the cases all of these symptoms will show together making it easier to detect the faulty component. As youre already aware the throttle plate position constantly changes as you step on or off the accelerator pedal.

In a nutshell the throttle position sensors job is to let the PCM know the throttle plate position angle as it opens or closes. Check out free battery charging and engine diagnostic testing while you are in store. Throttle Position Sensor Replacement 112 - 154 in Meridian ID.

EGR Valve Replacement 245 - 379 in King George VA. If the throttle position sensor fails your ECU doesnt know how much air is passing through the valve. Top 6 Bad Throttle Position Sensor Symptoms.

Below are common symptoms of a faulty TPS. On top of low prices Advance Auto Parts offers 8 different trusted brands of Throttle Position Sensor products for the 1995 Chevrolet S10. Replacement Idle Control Valve and Throttle Position Sensor Kit.

It can also cause problems when changing gears or setting base ignition timing. Hey guys here with a quick how-to video on the infamous Chevy Throttle position sensor install. CHEVROLET 1996 S10 PICKUP 43L V6 Fuel Air Throttle Position Sensor TPS Price.

You have 0 Items In Your Cart. Head Gasket Replacement 761 - 927 in Rocky River OH. The throttle position sensor reports the position of the gas pedal to the computer in your car Engine Control Unit.

The best part is our Chevrolet S10 Throttle Position Sensor products start from as little as 2284. Chevrolet S10 Throttle Position Sensor TPS - Best Throttle Position Sensor TPS Parts for Chevrolet S10 - Price 2199. The throttle position sensor or TPS monitors the throttle body butterfly valve.

A faulty throttle position sensor sends incorrect information to the ECM resulting in various issues in the engine its performance and fuel economy. The cool thing about the TPS test is that its done with a simple multimeter. Order Chevrolet S10 Blazer Throttle Position Sensor TPS online today.

HOW TO TEST CAMSHAFT POSITION SENSOR DEMONSTRATED ON BMW Our Website. Thats why a professional should scan your vehicle and detect what the particular fault is.

Cmp Camshaft Position Sensor Testing Freeautomechanic

Cmp Camshaft Position Sensor Testing Freeautomechanic

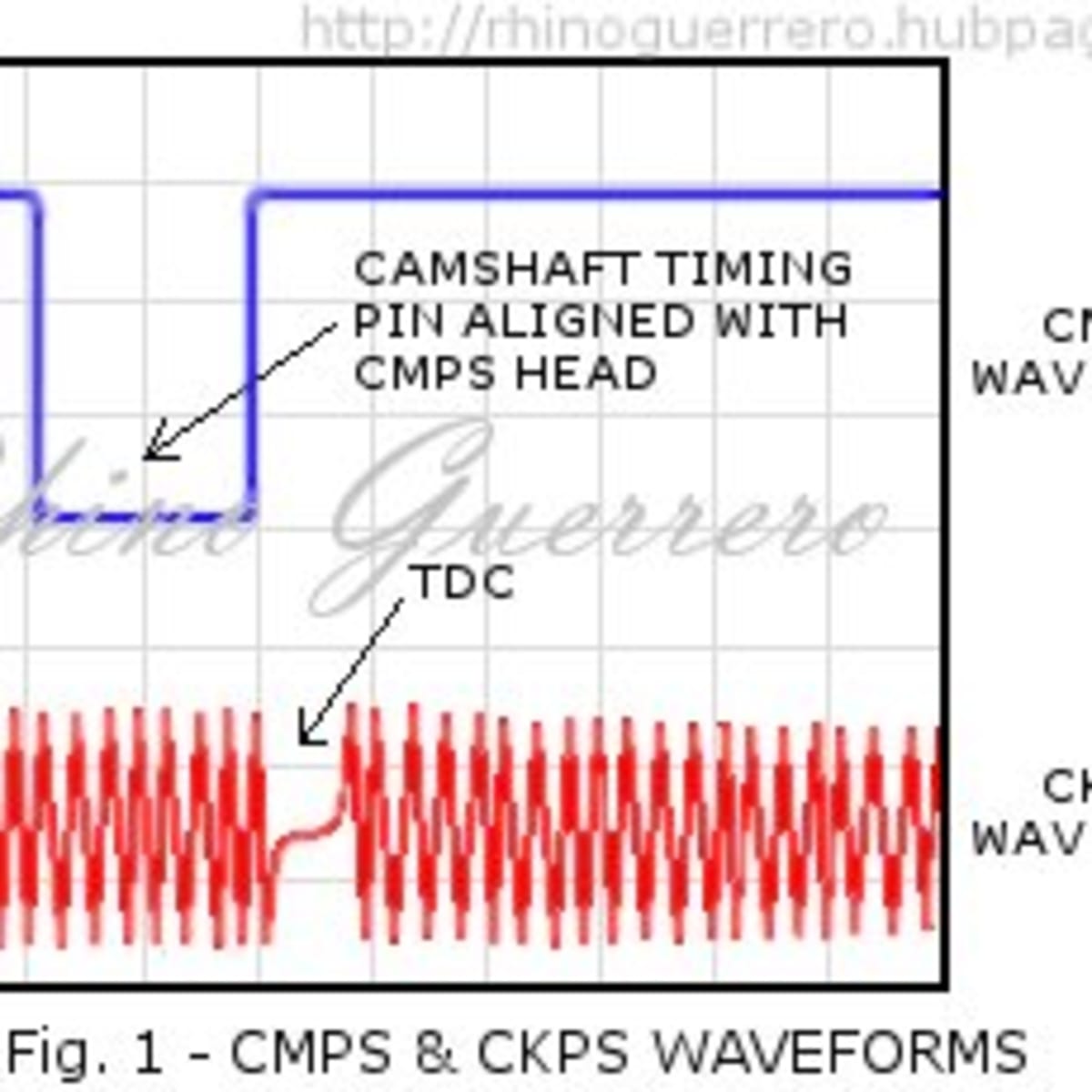

The result is an AC sine wave voltage that the on-board computer uses to determine camshaft position.

Testing a camshaft position sensor. So it is important to troubleshoot the CKP when you suspect CKP problems to make sure the problem is with the sensor the circuit or one of the components in the system it works with. Testing The Camshaft Position Signal To start off our camshaft position CMP sensor diagnostic were gonna verify that the CMP sensor is creating an ONOFF voltage signal as we crank the engine. Consult your owners manual to determine the location of your camshafts and sensors.

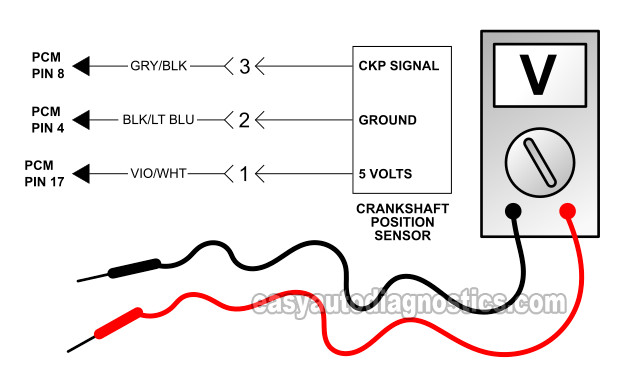

Move your vehicle to a well-lit area. How To Test Crankshaft And Camshaft Position Sensors. Testing A Three-Wire Sensor.

Set your multimeter to Ohms and touch your meter leads to the sensor terminal pins. The check engine indicator is on. In the camshaft sensor a magnetic field supplied by a permanent magnet in the sensor is allowed to surround a conductor in the sensor.

ON is when the signal output is 12 Volts and OFF is when the signal outputs 0 Volts. This may make it seem like every single one is tested in a different way. Here is how you can easily test both your crankshaft position sensor and camshaft position sensor.

Turn it off and wait several hours for the engine to cool off. Testing A Two-Wire SensorIn the two wire system the magnetic type you need to do the resistance test first. Testing The Camshaft Position Signal Generally when the camshaft position.

ON is when the CMP signal reads 5 Volts DC and OFF is when it reads 0 Volts DC on the multimeter. Not only that but these sensors are called by so many different names like. If your engine uses a camshaft position CMP sensor you can also see a related code.

No scan tool required for the cam sensor test since a scan tool is not gonna be much help. Its very important to be able to test these sensor since. Remove the retaining bolt and hold-down clamp.

However here you should note that this indicator can also light up for other reasons. How To Test The Camshaft Position Sensor 1997-1999 Ford 46L 54L The cam sensor on your 46L or 54L Ford pick up or SUV is a variable reluctance type sensor that has two wires coming out of its connector. Remove the camshaft position sensor retaining screws and sensor.

As soon as the camshaft position sensor has certain faults then the light of this indicator will come on. Look up the resistance value for your sensor in your vehicle repair manual. Testing The CMP Signal With A Multimeter The camshaft position sensor produces an ONOFF voltage signal as the engine turns.

1 cylinder at 10ATDC then matchmark the CMP sensor terminal connector position with the engine assembly. Testing the cam sensor inside the distributor on all 43L 50L and 57L GM equipped mini-vans pick ups and SUVs can be easily and accurately done with just a multimeter. The next sections will help you test your CKP sensor using only a digital multimeter DMM whether your engine uses an inductive or Hall effect type sensor.

The sensor consists of a permanent magnet core and coil. In laymans terms this means that the signal voltage alternates between 10 Volts and 0 Volts the entire time the engine is running. Checking The Camshaft Position Signal With A Multimeter The camshaft position sensor on your Nissan Sentra is designed to produce and on off voltage as the engine turns.

In plain English this means that this type of cam sensor can easily be tested with a multimeter in Volts AC mode. Crankshaft Camshaft Position Sensor Testing Done The Easy Way. You can also measure your CMP sensor resistance.

The oil pump intermediate shaft should be removed with the camshaft sensor housing. How to Test Cam Sensors With an Ohm Meter Step 1. Camshaft position sensor resistance test.

Today were testing the camshaft position sensor along with its harness connector. If there is infinite resistance the sensor is open and you need to replace it. As the camshaft turns a toothed gear on the camshaft passes through the field and causes it to collapse.

Set your meter to.

The symptom starts with difficulty in starting and leaves the car dead one day if you dont get it fixed. Check Engine Light CEL Service Engine Warning may turn on and you will have a fault code related to the CAM sensor.

Crankshaft Position Sensor W220 S Class Encyclopedia

Crankshaft Position Sensor W220 S Class Encyclopedia

Damage to the crankshaft position sensor is sometimes caused by leaking oil which means there may be another component of your vehicle that needs replacement or repair.

Mercedes crankshaft position sensor symptoms. How to Tell if your Mercedes has a Faulty Crankshaft Position Sensor. Symptoms of a Bad or Failing Crankshaft Position Sensor. Cost of diagnosing the P0016 MERCEDES-BENZ code Labor.

Damaged or cut wiring. One of the most serious crankshaft position sensor symptoms photo source. Issues Starting the Vehicle.

Over time the camshaft position sensor can fail or become worn down due to accidents or normal wear and tear. Check Engine Light Comes On. As your sensor drifts out of range your ECU detects a malfunction and turns on the dashboard warning light.

The computer receives a malfunction code when the sensor is completely gone. As the crankshaft position sensor is an electronic component the reasons why it fails largely follows the same reasons as the other electronic systems of your Mercedes. If the crankshaft position sensor isnt working right your fuel injection wont work as efficiently.

Upon scanning for trouble codes with an OBD2 scanner you may see crankshaft position sensor related codes such as P0335 or P0340. Problems with the crankshaft position sensor will often present as problems with engine timing. No fuel no run.

In this tutorial we show you how to change the crank sensor for the mercedes benz. Intermittent starting This is a very common problem if the Camshaft Sensor starts to fail. Your gas mileage will suffer as a result.

Symptoms of a defective crankshaft position sensor on a Mercedes-Benz Engine Cranks but no Start Dies Stalls or Backfires A failed crankshaft position sensor can cause your engine to stall or not start at all. Your Mercedes-Benz may start and run for a short time or until it gets warm and then it dies. The engine wont start.

The auto repair labor rates vary by location your vehicles make and model and even your engine type. The computer wont provide the engine with spark without a crankshaft position sensor signal. These are all issues you can detect as a driver.

If you are experiencing any of these other symptoms in addition to the check engine light then that increases the likelihood that the crankshaft position sensor is to blame. Make sure they also check for a bad crank sensor if the problem still persists. Symptoms of Bad or Failing Crankshaft Position Sensor.

This could mean that your car isnt receiving the right amount of fuel needed to run. There are a few warning signs to watch out for before your camshaft position sensor. There can be many reasons that your check engine light comes on but a faulty camshaft position sensor is a common cause.

You may notice the car starts fine one day and then hesitates to start the next. If the engine runs it will run poorly and get bad fuel mileage. However other mechanics that I respect believe its the mounting location and improper insulation from heat.

In my opinion the Mercedes-Benz crankshaft position sensor problem boils down to a naturally occurring vibration from the engine design. If the engine runs for a long period of. When the computer senses the engine is out of time it will turn on the check engine light and the engine may start and stall or fail to start at all.

What are the symptoms related to a bad crankshaft position sensor. The most common symptom associated with a bad or failing crankshaft position sensor is difficulty starting the vehicle. The check engine light illuminates for many reasons one of which is sensor failure.

The engines computer relies on information from crankshaft position sensor for ignition system control. The electrical connector can also be damaged and should be inspected every time the position sensor is replaced. Christopher Brummett Its one of the most serious crankshaft position sensor symptoms.

10 The cost of diagnosing the P0016 MERCEDES-BENZ code is 10 hour of labor. Your fuel economy suffers. Metal abrasion causing soiling and contamination.

Stalling or Trouble Starting Similar to cylinder misfiring the crank sensor could be sending the wrong information to the ignition system. Bad or Failing Crankshaft Position Sensor Symptoms There are a number of reasons why a crankshaft position sensor can fail and a number of symptoms associated with that failure.

A faulty cam sensor could disrupt the timing of your engines stroke cycle. Testing some pull down type sensors.

Crankshaft Position Sensor How It Works Symptoms Problems Testing

Crankshaft Position Sensor How It Works Symptoms Problems Testing

The vehicle stops repeatedly.

Testing camshaft position sensor. For our first test well connect a multimeter to the CMP signal wire and check to see if the sensors signal voltage is switching between 5 Volts and 0 Volts. In plain English this means that this type of cam sensor can easily be tested with a multimeter in Volts AC mode. I have pulled a P0340 code.

Set your multimeter to Ohms and touch your meter leads to the sensor terminal pins. Crankshaft Camshaft Position Sensor Testing Done The Easy Way. Here a vehicle may accelerate slowly the engine power has decreased or the fuel consumption is inadequate.

Testing the camshaft position sensor andor a Code P0340 No cam signal al PCM on your Chrysler or Dodge or Plymouth or Eagle equipped 20L or 24L 4 cylinder is an easy test that you can accomplish with a multimeterYou dont need a scan tool to follow the test steps in this article. Cam sensor resistances and the location of the sensor vary with your vehicles make and model. I am testing the camshaft position sensor with a meter plugged into the connector that goes to the ECU.

You dont need a scan tool to test the Ford 46L 54L camshaft position sensor although a scan tool does come in handy to read the diagnostic trouble codes. The sensor must be removed for resistance testing with a multimeter. This is how a sensor look like SEE MORE.

Know the Functionality of the Crankshaft Position Sensor. Camshaft position sensor resistance test. If you suspect that the camshaft position CMP sensor on your 1996-1997 39L Dodge Ram pickup is bad and causing a no-start problem or a trouble code P0340 then this is the tutorial you need to test it.

Also the following camshaft position sensor test is an on car test that will verify if the CMP sensor is. Here is how you can easily test both your crankshaft position sensor and camshaft position sensor. With the ignition OFF disconnect the CMP sensor.

For this reason you may know some useful signals that will let you know if you need to repair or replace any component. When a Crankshaft Camshaft Position Sensor goes BAD your vehicle will not start. Its very important to be able to test these sensor since.

At some points the camshaft position sensor may fail due to wear over time. Simple tests of a Hall Effect Type Camshaft Position Sensor using a MultiMeter. Aslo a resistance test of the cam sensor will get you no-where since the camshaft position sensor is a Hall Effect type sensor that can not be Ohm-ed resistance tested with a multimeter.

If there is infinite resistance the sensor is open and you need to replace it. Look up the resistance value for your sensor in your vehicle repair manual. HOW TO TEST CAMSHAFT POSITION SENSOR DEMONSTRATED ON BMW Our Website.

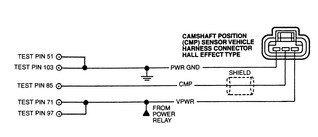

The typical camshaft position sensor is a cylindrical-shaped device about 3 inches long and installed in the side of the engine block. This is a sample for 2 and 3 wire sensor. If the reading is greater than 105 volts the power circuit to the sensor is okay.

Camshaft Position Sensor Testing Three-Wire Sensors. Testing its electrical resistance with an ohmmeter or multimeter allows you to troubleshoot the cam sensor. Well testing the sensors is the way out once you find out the.

This is according to the test procedure by Chilton Hayes and Volvo. Some Common Crankshaft Position Sensor Symptoms. No scan tool required for the cam sensor test since a scan tool is not gonna be much help.

Testing The Camshaft Position Signal Generally when the camshaft position sensor fails itll usually stay stuck producing a single voltage value as the engine turns. With the ignition ON and the engine OFF measure the voltage between sensor harness connector VPWR and PWR GND terminals refer to the accompanying illustration. April 7 2020 Engine Testing Ignition System.

Lets move further on test crankshaft and camshaft position sensors How To Test Crankshaft And Camshaft Position Sensors. I do not have an account with Alldata. The aim of this tutorial is to walk you thru the whole thing step by step.

The cool thing is that the camshaft position sensor can be diagnosed as good or bad in 3 tests and theyre not difficult to perform. It calls for testing the values at the harness on the engine side unplugged from the sensor. You can also measure your CMP sensor resistance.